What do a non-stick pan, a raincoat and a medical stent have in common? They all have water-repelling properties that resist water uptake or degradation by hydrolysis. Hydrophobicity, the capacity to not interact with water, is important as we are consistently in contact with water in the external environment and inside our cells.

A recent collaborative study between three laboratories at Tufts found that silk fibroin protein can be modified to have significantly high hydrophobicity. Krishna Kumar, a chemist at Tufts and co-author of the study, explained the necessity of having materials that refuse to stick to water.

“In biology, if you take any material, whether it be plastic, things that we think are not very reactive, eventually there will be some adhesion, where cells and gunk and debris get stuck. And then those become sites of other things, like pathogenic bacteria,” Kumar said. For something to be long lasting in biology, Kumar explained that it needs to be water repellent and less likely to interact with other entities.

It may be difficult to conceptualize that silk — a soft, fragile material commonly used in textiles — is almost as strong as stainless steel, according to the researchers. Silk is a versatile material that can be chemically changed to adopt different characteristics.

“It’s all about how the silk is processed, and how we put that naturally derived material to work,” Morgan Hawker, physical chemist at Fresno State University and second author of the paper, said.“We don’t simply just use the silk cocoon directly, but there are lots of processing steps that we can do and material chemistry approaches that we can take to change the mechanical properties of the silk.”

To transform the silk from cocoons into the final product of hydrophobic silk films, the researchers undertook a multi-step process that involves collaboration across three laboratories on campus — the Kaplan, Kumar and Davis Labs.

The Kaplan Lab begins the assembly line by supplying the cocoons, from which silk fiber, also known as the fibroin protein, is extracted to create a base or surface on which the chemical modifications can act.

The freshly isolated silk fibroin protein from the cocoon is not highly reactive. It must be further modified by adding amine groups onto the protein to increase reactivity. The Kumar Lab then attaches perfluorocarbon chains onto the silk, which makes the product hydrophobic.

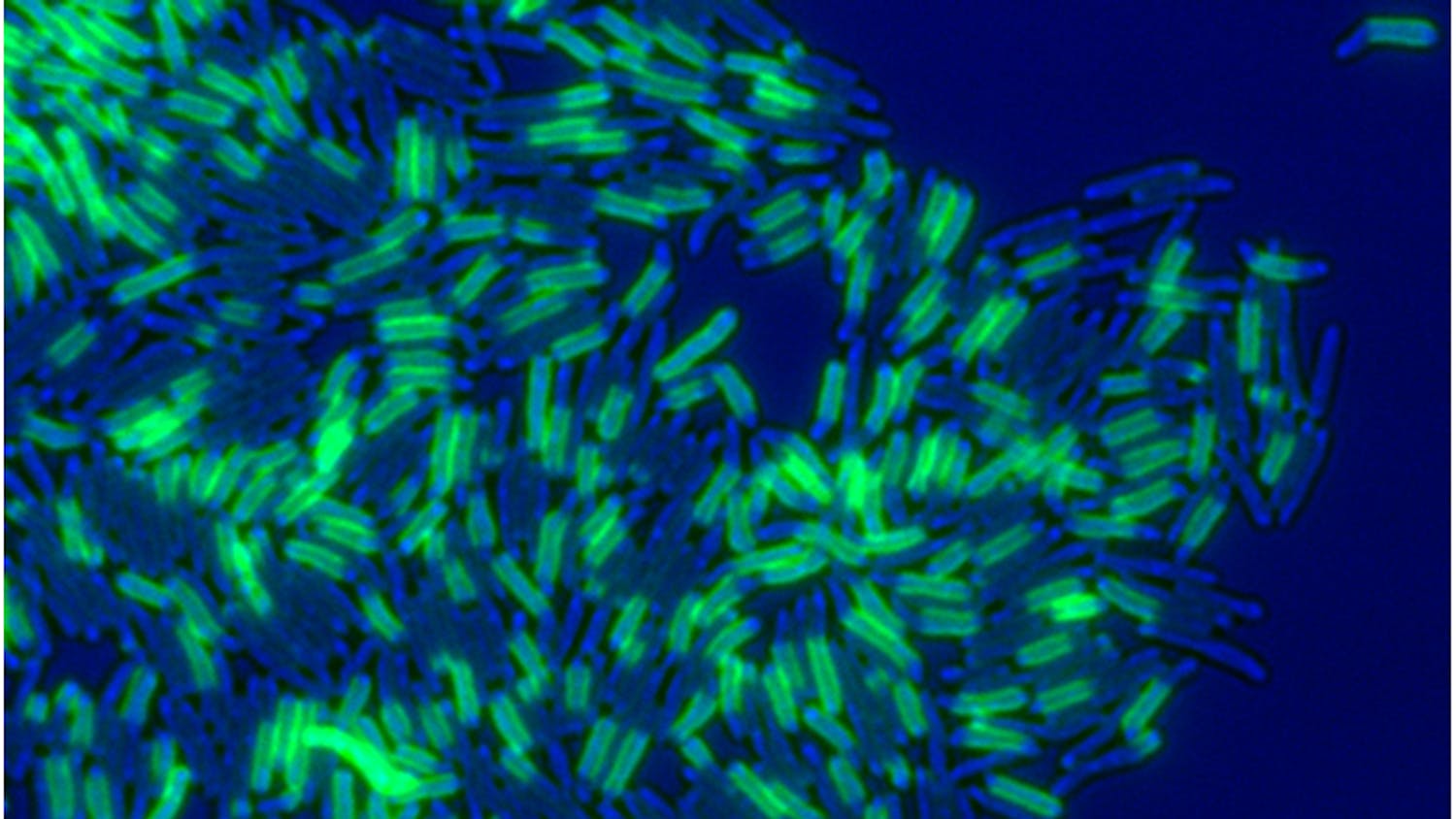

The Davis Lab lastly confirms the hydrophobicity of these modified proteins by visualizing its fluorine content using spectroscopy imaging techniques.

Julia Fountain, chemist and first author of the study, emphasized the value of collaboration in research and noted the critical contributions that each lab brought to make this project possible.

“This project was a huge effort between many research labs. … The ability to collaborate between departments and across fields is an amazing thing that scientists can do and we should all be able to foster connections like that,” Fountain said.

Hawker, who worked more on the biomaterial and silk preparation side, indicated that progressing the silk to a state where it can be modified was a substantial obstacle.

“I think the most challenging part was getting to the point where we were able to have a material that could be modified with the chemistry at [the Kumar Lab],” Hawker said. “Getting to that amine-rich material took several months because we had started off in a different direction and we had to change partway through in terms of the type of chemistry that we were using to get that starting material.”

Hydrophobicity is measured by observing how water behaves on a slide, which is molded from the modified silk fibroin protein. Imagine water droplets placed on wax paper compared to a regular sheet of printing paper. The water droplets would “ball up” on the wax paper because the surface is water repellent, whereas the same droplets would spread on a regular piece of paper because it is not hydrophobic. The same concept applies to how hydrophobicity is measured for the silk films.

“We have the surface, then you put a drop of water, and then you measure how much it’s balling up and how tightly [the water is bound to itself]. We measure the angle that [the water droplet] is making,” Kumar said.

Fountain recalled the moment when she first observed hydrophobicity on the silk films.

“I just remember that contact angle and seeing it on the screen and being like, ‘Wow, I made a hydrophobic material from something that originally wasn’t,’” she said. “That was very gratifying as a young chemist.”

Kumar noted that the modified silk proteins can have unprecedentedly high hydrophobicity and completely repel water.

“Right now [the modified silk proteins] are super hydrophobic, meaning that [they] are more hydrophobic than Teflon,” Kumar said. “We think we could probably make the world’s most hydrophobic material.”

Hawker further echoed the importance of hydrophobicity in biology.

“We think about biological materials as always needing to promote attachment of particular types of cells or proteins or other biological species, but really, there’s a huge world out there for nonattachment,” Hawker said.

As a next step in the research, the lab hopes to explore the biocompatibility of the hydrophobic silk material and its potential to act as a GPS tag that guides mammalian cells to specific parts of the body.

“There are hundreds of chemicals, like thousands of trillions of chemicals in our body, and the main thing is who’s interacting with whom,” Kumar said. “So [the hydrophobic tag] is almost like a passport that interacts with only [the destination] and nothing else.”